- Suitable For: bonding roofing felts

- Area of use: EXT

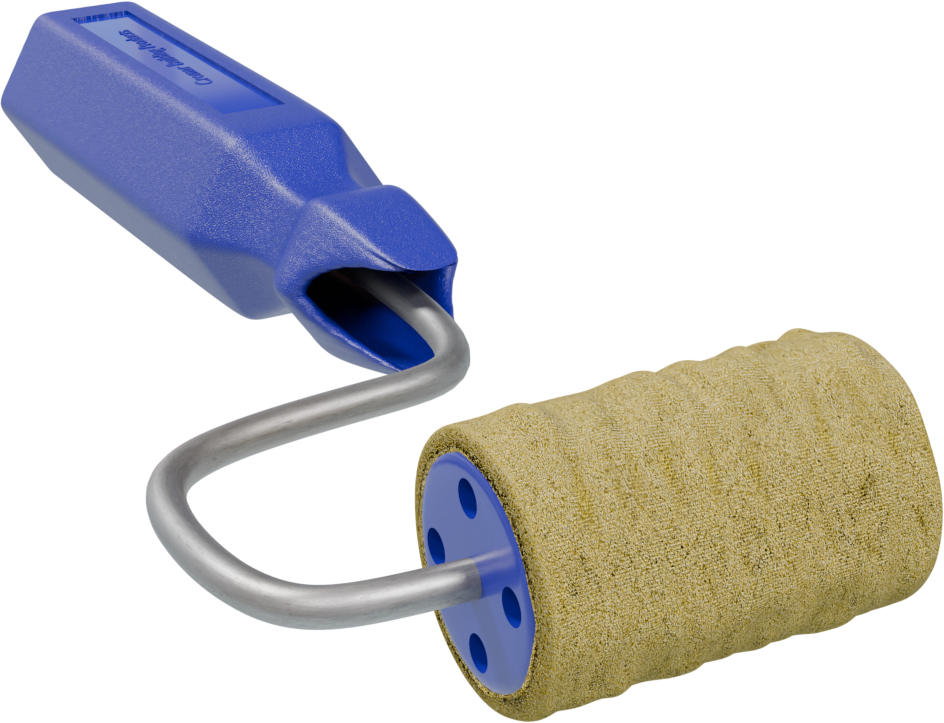

- Application Method: brush/mop/squeegee

- Time to full cure: 24 hours

- Volume: 5L 25L

- Container Type: tin

- Type: bitumen

- Colour: black

- Brand: Cromar

- Manufactuer: Cromar

- Box Size: Single Box

Data Sheets

Cromar Roofing Felt Adhesive is a solvent-based, cold-applied bituminous adhesive designed for superior performance. Crafted for both convenience and safety, this adhesive guarantees affinity and a robust final bond to bituminous membranes. Below are its key features:

- Versatile Application: Ideal for bonding roofing felts to various substrates including metal, timber, concrete, and asphalt, ensuring broad compatibility and flexibility in usage.

- Lap Cement: Facilitates secure bonding of successive layers of roofing felt, providing a durable and watertight seal for enhanced protection against the elements.

- Chippings Bonding: Suitable for bonding chippings to flat roofs, offering reliable adhesion for added durability and weather resistance.

- Strong Final Bond: Formulated to deliver a strong and enduring bond, ensuring long-lasting performance and peace of mind for your roofing projects.

Experience the convenience and reliability of Cromar Roofing Felt Adhesive for all your roofing bonding needs.

For more information on Cromar, you can visit their website here.

Cromar Roofing Felt Adhesive bonds roofing felts to metal, timber, concrete, and asphalt, acts as lap cement, and effectively bonds chippings to flat roofs.

APPLICATION

- Application Method:

- Use a stiff brush, mop, or squeegee to apply Cromar Roofing Felt Adhesive.

- Store the adhesive in a warm room overnight before use in cold weather to prevent thickening.

- Application Process:

- Apply the adhesive to the surface and let it sit for 15 to 30 minutes (depending on drying conditions) to reach full thickness.

- Carefully place the felt into the wet adhesive film, ensuring maximum contact by rubbing or rolling each section down.

- Overlap and Bonding:

- Maintain overlaps of at least 75mm on the sides and 150mm at the ends.

- Apply adhesive underneath the felt for complete bonding, particularly at side and end laps.

- Additional Considerations:

- On timber structures, nail down the first layer of felt and use the adhesive for successive layers.

- Prime porous concrete surfaces before applying felt.

- After 24 hours, check all bondings, especially laps, to ensure full adhesive coverage.

You must be logged in to post a review.

| Elementlength | |||||||

| up to 1,5 m |

up to 2,5 m |

up to 3,5 m |

up to 4,5 m |

up to 2,5 m |

up to 3,5 m |

up to 4,5 m |

|

| Type of window frame material |

Minimum witdth of joints for a butled mounting b in mm |

Minimum witdth of joints for a inner mounting b in mm |

|||||

| Hard PVC (white) | 10 | 15 | 20 | 25 | 10 | 10 | 15 |

| Hard PVC and PMMA (dark) (colour extruded) |

15 | 20 | 25 | 30 | 10 | 15 | 20 |

| Hard PUR integral foam | 10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Wood-aluminium-window | 10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Aluminium-plastic sandwich frame (bright) |

10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Aluminium-plastic sandwich frame (dark) |

10 | 15 | 20 | 25 | 10 | 10 | 15 |

| Wooden window frame | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

Reviews

There are no reviews yet.