- Suitable For: protecting against staining and loss of jointing sand

- Area of use: EXT

- Application Method: brush/roller

- Volume: 5L 25L

- Container Type: bottle

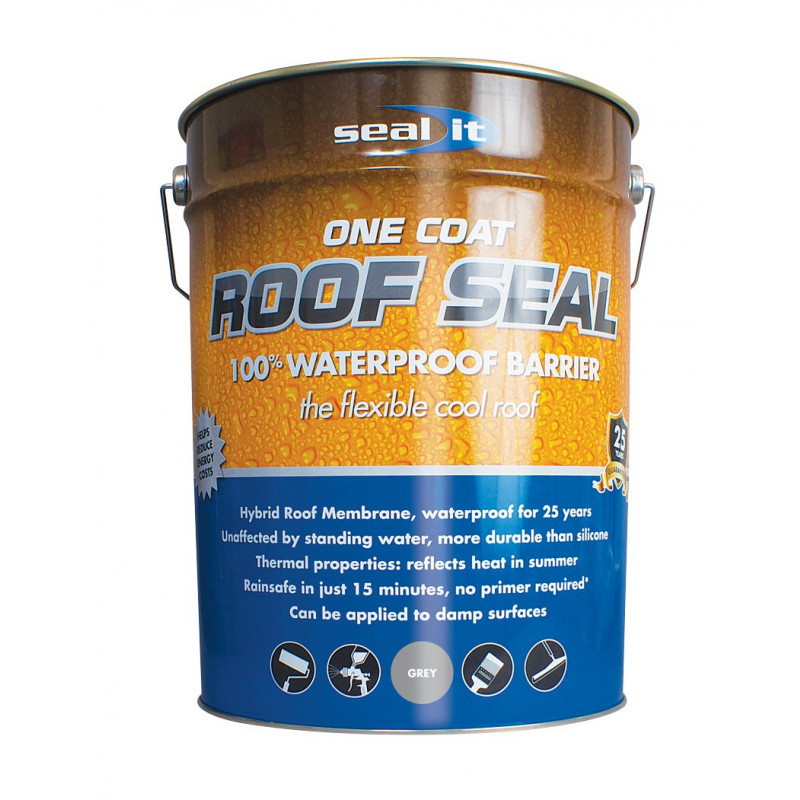

- Type: sealant

- Colour: clear

- Brand: AlphaChem

- Manufactuer: Cromar

- Box Size: Single Box

Cromar AlphaChem Block & Paving Seal is a robust solution for safeguarding block pavers and masonry. It offers long-lasting protection to a diverse range of materials, including concrete, screeds, brickwork, masonry, and fibrous sheet materials.

Effective Protection: Formulated to provide durable penetrative sealing, Block & Paving Seal effectively shields various surfaces against water infiltration and air-borne pollutants.

Versatile Application: Suitable for both new and existing concrete and masonry, this sealer offers versatile protection across different projects.

Enhanced Durability: With Block & Paving Seal, users can expect prolonged durability, ensuring lasting defense against environmental elements.

Peace of Mind: Backed by quality assurance, Block & Paving Seal offers reliable protection, giving users peace of mind for their projects’ longevity and resilience.

The coverage will vary depending on the porosity of the substrate. As a guideline, expect coverage of approximately 6m² per liter.

For optimal storage, keep in a cool, dry area, away from direct heat or open flames. Ensure containers are tightly sealed when not in use.

For more information on our range of sealants, please click here. Alternatively, for our full range from Cromar, click here.

For more information on Cromar, you can visit their website here.

Cromar AlphaChem Block & Paving Seal offers a resilient penetrative sealing solution for an extensive range of materials, encompassing concrete, screeds, brickwork, masonry, and fibrous sheet materials. By employing Block & Paving Sealer, users ensure protection for both newly laid and existing concrete and masonry structures, guarding them against the detrimental effects of water infiltration and airborne pollutants.

APPLICATION

- Ensure all surfaces are dry, sound, and free from oil, grease, treatment debris, and algae.

- New concrete should cure for 4 to 6 weeks before applying the treatment.

- Avoid application if rain is expected within 3 to 4 hours after application.

- Conduct a small test application in doubt, leaving it for 24 hours.

- Apply using a brush or roller, working the product well into the surface while being careful not to brush out jointing sand.

- Apply one or two coats depending on the desired effect, allowing 2 to 3 hours between coats.

- Allow the product to fully cure for at least 48 hours before allowing any traffic on the treated area.

- Clean equipment with soapy water after use.

You must be logged in to post a review.

| Elementlength | |||||||

| up to 1,5 m |

up to 2,5 m |

up to 3,5 m |

up to 4,5 m |

up to 2,5 m |

up to 3,5 m |

up to 4,5 m |

|

| Type of window frame material |

Minimum witdth of joints for a butled mounting b in mm |

Minimum witdth of joints for a inner mounting b in mm |

|||||

| Hard PVC (white) | 10 | 15 | 20 | 25 | 10 | 10 | 15 |

| Hard PVC and PMMA (dark) (colour extruded) |

15 | 20 | 25 | 30 | 10 | 15 | 20 |

| Hard PUR integral foam | 10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Wood-aluminium-window | 10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Aluminium-plastic sandwich frame (bright) |

10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Aluminium-plastic sandwich frame (dark) |

10 | 15 | 20 | 25 | 10 | 10 | 15 |

| Wooden window frame | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

£7.60 ex. VAT

Reviews

There are no reviews yet.