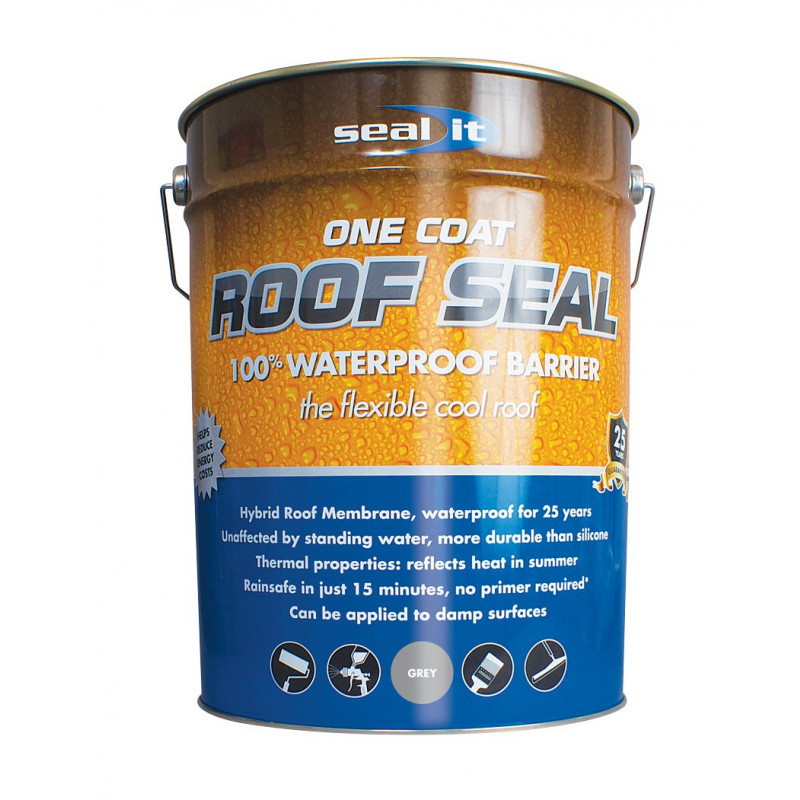

- Suitable For: waterproofing

- Area of use: EXT

- Application Method: brush

- Volume: 25L

- Container Type: bottle

- Type: waterproofing

- Colour: black

- Brand: Cromar

- Manufactuer: Cromar

- Box Size: Single

Data Sheets

Cromar Roofing Emulsion is a bituminous waterproofing treatment applied with a brush, ideal for weatherproofing various roof surfaces.

Roof Waterproofing: Cromar Roofing Emulsion offers a cost-effective and durable waterproofing solution, ideal for application under favorable drying conditions. It is suitable for various surfaces including concrete, fiber/cement, roofing felt, mastic asphalt, corrugated iron, slates, tiles, lead, copper, and zinc, providing effective water and moisture resistance.

Metal Protection: Cromar Roofing Emulsion also serves as a protective layer against corrosion for pipes, structural steelwork, and other metallic equipment.

Insulation: Utilize Cromar Roofing Emulsion to create a vapor barrier in environments such as cold storage rooms, mushroom houses, and similar installations.

For more information on Cromar, you can visit their website here.

Cromar Roof Emulsion is ideal for weatherproofing most types of roof surfaces.

APPLICATION

- Stir well before use.

- Apply by brush.

- Two coats are required at a rate of 0.75 liters per square meter per coat.

- Allow 24 hours between coats and apply each coat at right angles to the previous one.

- Cromar Roofing Emulsion can be applied to a damp surface, but both the coating and the surface must be able to dry before the emulsion cures to a waterproof film.

- For enhanced strength, durability, and flexibility, consider reinforcing the coating with an open woven glass fiber membrane embedded into the first coat, ensuring a minimum of 50mm overlap.

- Over-coat with two successive coats of Cromar Roofing Emulsion at the same coverage rate.

- To extend the effective life of the dried coating, it’s advisable to over-coat it with a suitable decorative, solar reflective paint.

- Protect from rain and frost until cured.

Drying time is influenced by external factors such as temperature, humidity, and wind speed. Thicker applications will take longer to dry and are more prone to wash off during the initial drying stages. Typically, under standard conditions, the product will dry within 4 to 6 hours, but it’s recommended to allow 24 hours between coats. Note that the coating may be deemed dry when rubbing with a wet finger does not leave a brown stain.

You must be logged in to post a review.

| Elementlength | |||||||

| up to 1,5 m |

up to 2,5 m |

up to 3,5 m |

up to 4,5 m |

up to 2,5 m |

up to 3,5 m |

up to 4,5 m |

|

| Type of window frame material |

Minimum witdth of joints for a butled mounting b in mm |

Minimum witdth of joints for a inner mounting b in mm |

|||||

| Hard PVC (white) | 10 | 15 | 20 | 25 | 10 | 10 | 15 |

| Hard PVC and PMMA (dark) (colour extruded) |

15 | 20 | 25 | 30 | 10 | 15 | 20 |

| Hard PUR integral foam | 10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Wood-aluminium-window | 10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Aluminium-plastic sandwich frame (bright) |

10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Aluminium-plastic sandwich frame (dark) |

10 | 15 | 20 | 25 | 10 | 10 | 15 |

| Wooden window frame | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

£7.60 ex. VAT

Reviews

There are no reviews yet.