- Suitable For: sealing various substrates

- Area of use: INT & EXT

- Application Method: silicone gun

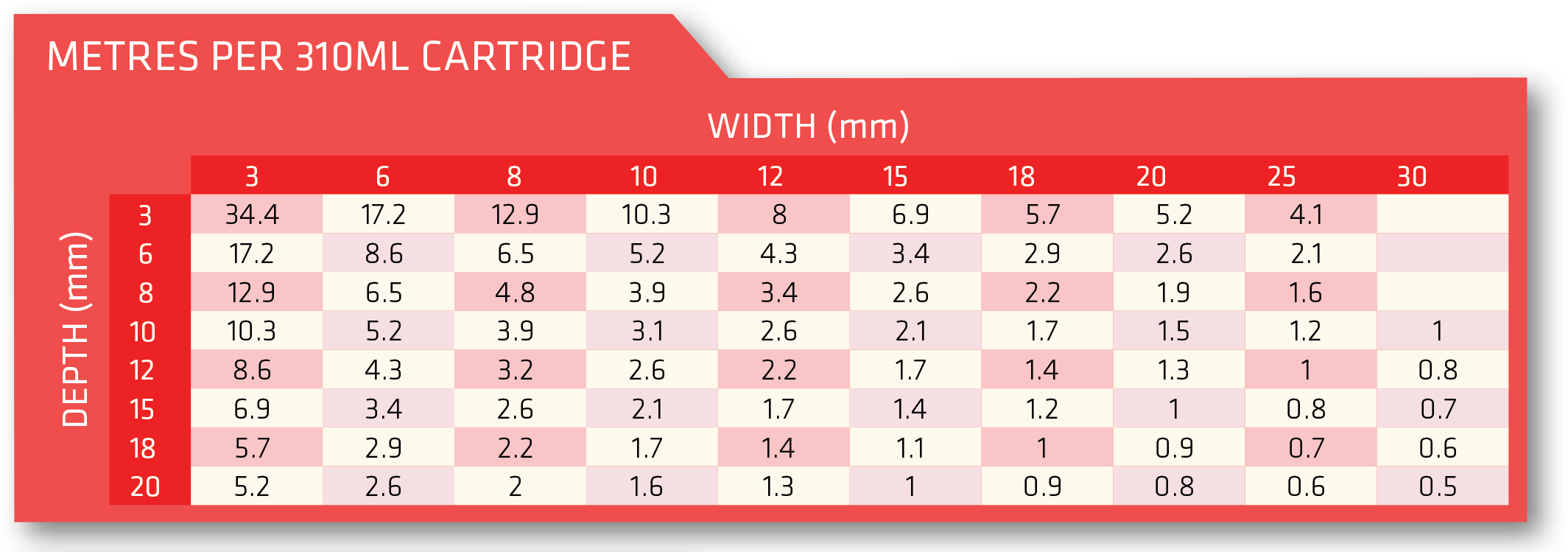

- Volume: 380ml

- Container Type: cartridge

- Type: sealant

- Colour: 10 colours

- Brand: AlphaChem

- Manufactuer: Cromar

- Box Size: Single Box

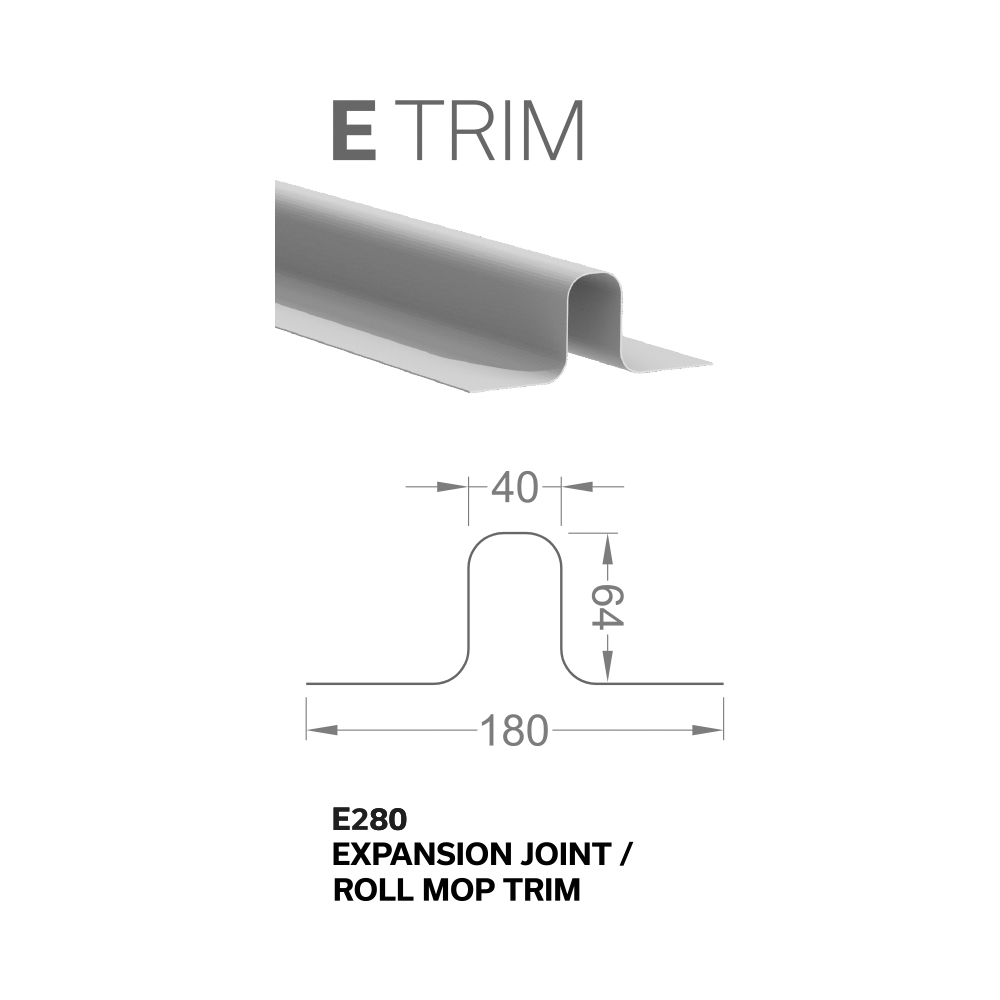

Cromar AlphaChem 800LMN+ is a premium-grade solution meticulously crafted for expansion joints and perimeter pointing.

Key Points:

- Rapid Curing & Low MEKO Formula: Engineered for efficiency, this silicone sealant boasts a fast curing time, reducing project downtime. Its low MEKO formula enhances application convenience without compromising performance.

- Superior Adhesion & Flexibility: Experience reliable bonding across a diverse range of construction substrates. With excellent adhesion properties, it ensures a secure seal for both indoor and outdoor applications, accommodating up to 25% maximum movement tolerance.

- Certified Quality & Reliability: Conforming to ISO 11600 F&G 25LM standards, EliteSeal guarantees consistent quality and reliability in every application. Trust in its certification for peace of mind in your construction projects.

- Versatile & Resilient: 8000LMN+ is built to withstand the elements, this sealant offers remarkable resilience against aging, weather, and UV exposure. Its compatibility with paints, metals, and plastics, including copper, adds versatility to its application, making it a go-to choice for various projects.

Trust in 800LMN+ for superior performance and enduring results in your construction endeavors.

For more information on our range of sealants, please click here. Alternatively, for our full range from Cromar, click here.

For more information on Cromar, you can visit their website here.

Cromar AlphaChem 800LMN+ is ideal for sealing and connecting joints in glass and window construction, metal structures, and porous substrates like concrete, plasterboard, and brick, this silicone is the ideal choice. However, it’s important to note that it’s unsuitable for certain applications. Avoid using it in aquarium construction, on marble or natural stone, for underwater applications, as a mirror adhesive, or in areas with direct food contact. Additionally, it’s not recommended for use with plastics that typically have poor adhesion to silicone.

APPLICATION

Substrate Pretreatment:

-

- Ensure the substrate is dry, firm, and free from dust and grease; clean with isopropanol if needed.

- Porous substrates such as concrete, plasterboard, and untreated wood require priming; remove any cement slurry, mold release agents, or impregnations before priming.

- In renovation projects, fully remove old sealant, remnants of paint, and loose material.

- Test compatibility with the sealant on coated substrates like paints and lacquers.

Joint Preparation:

-

- Always use a suitable, correctly dimensioned joint backing (e.g., PE cord, rock wool) to prevent adhesion on three faces.

- To maintain a clean joint and prevent contamination, consider masking the joint edges with adhesive tape before primer application and filling.

Joint Dimensions:

-

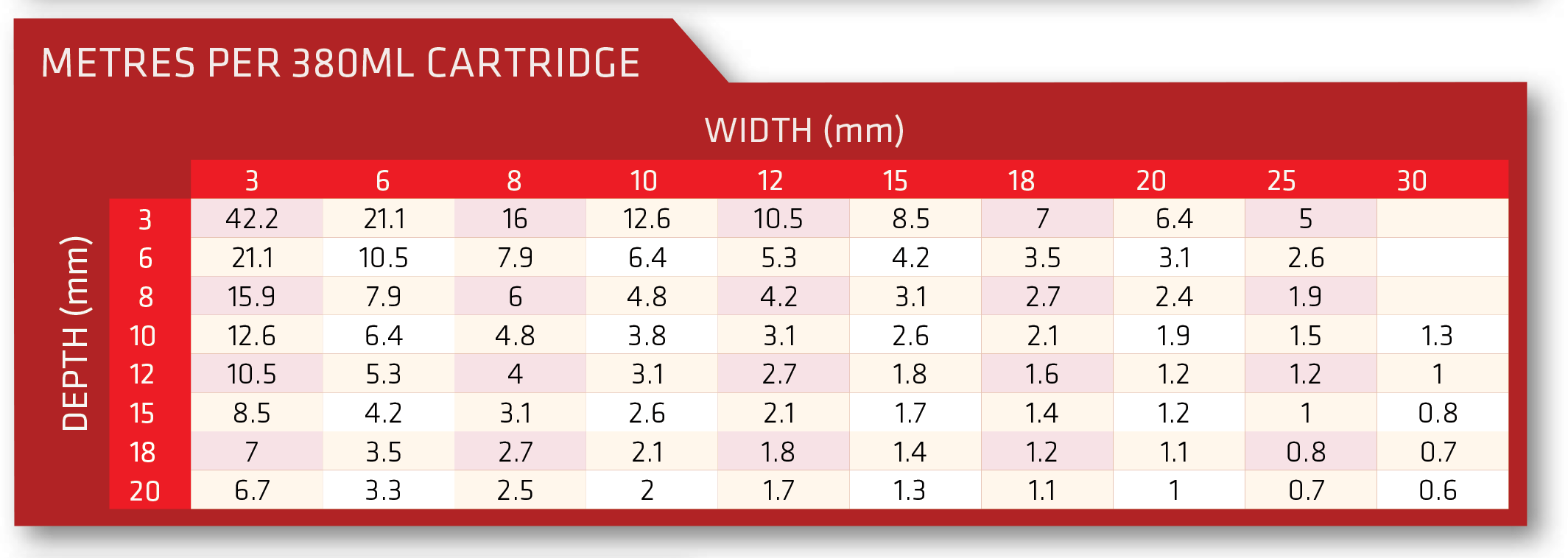

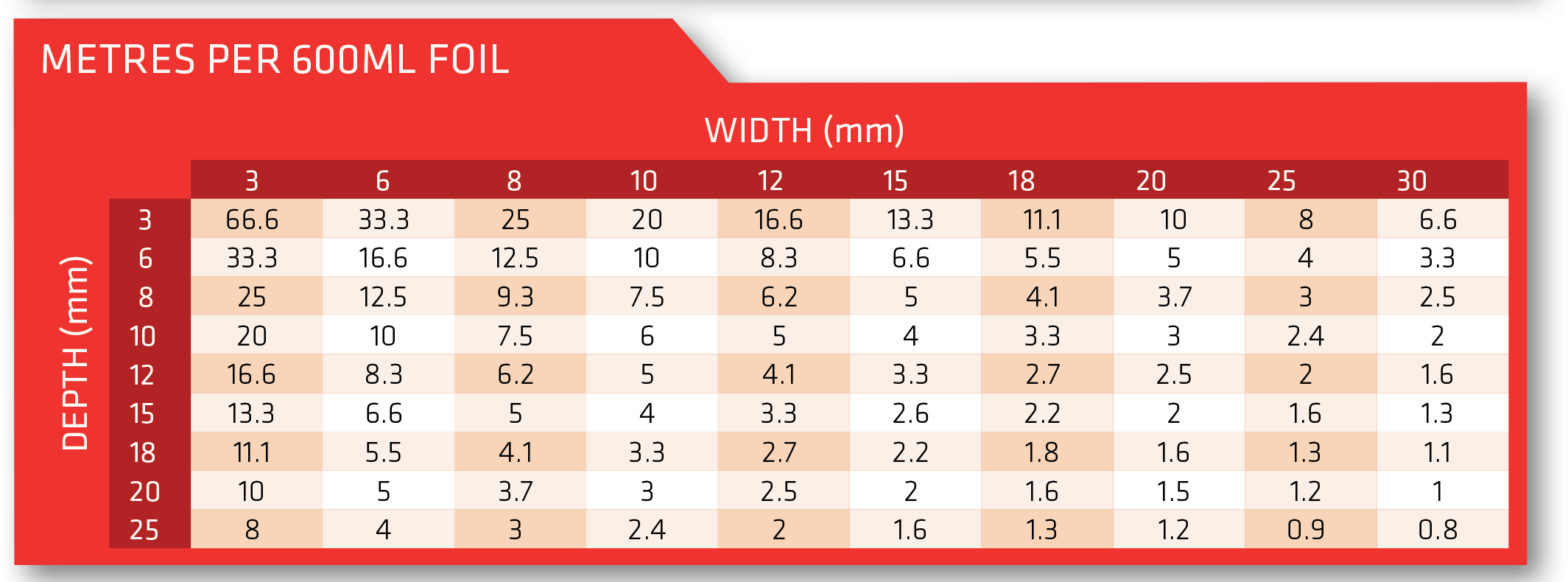

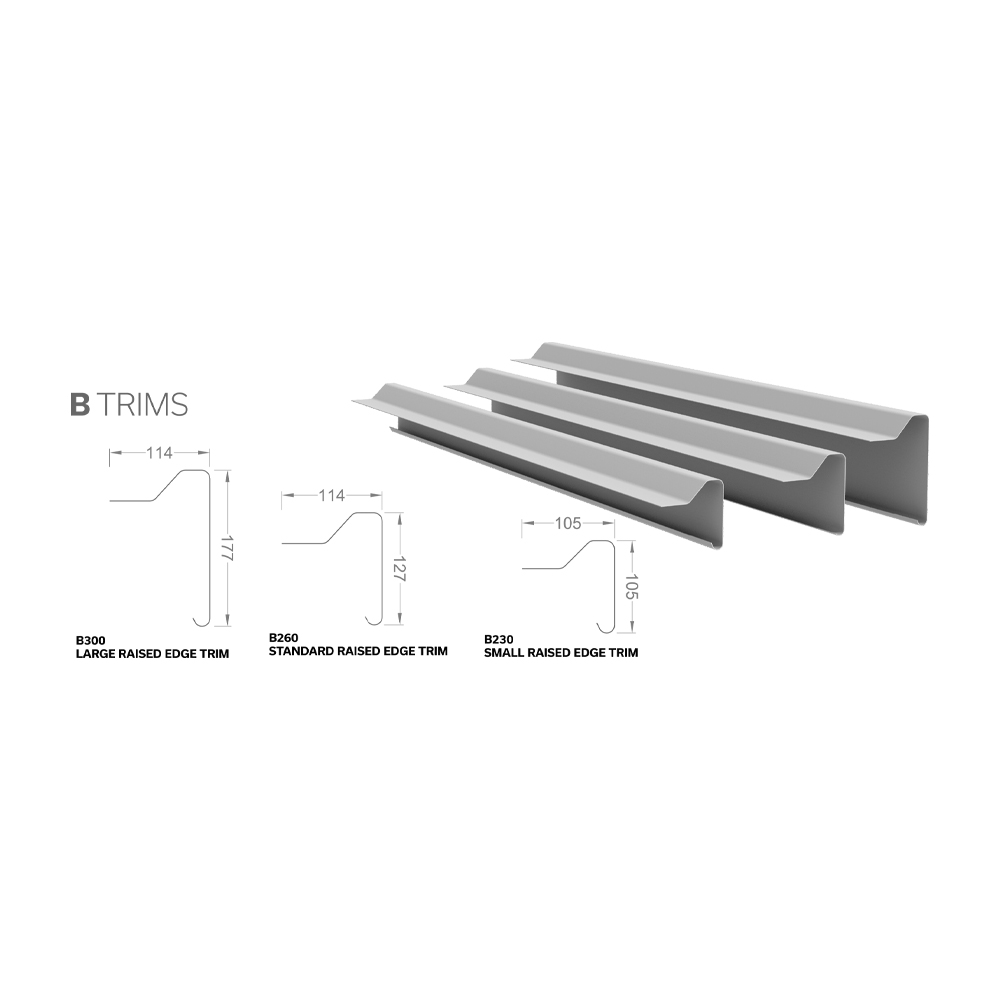

- For indoor applications, joint dimensions should be at least 5 x 5 mm; for outdoor applications, dimensions should be 10 x 8 mm (width x depth).

- Increase joint depth to roughly half the joint width for wider joints (up to 30 mm).

- Ensure triangular bevels have uniform sides of equal length with at least 7 mm bonding surface on each side.

Tooling:

-

- Apply the sealant with a suitable manual, battery-powered, or pneumatic caulking gun.

- Smooth the sealant in the joint using water or a neutral, non-staining water-based smoothing agent with a suitable tool (e.g., jointing trowel).

- Smoothing is recommended for optical reasons and to establish close contact and good adhesion to the substrate; remove excess smoothing agent to avoid schlieren.

- Remove any adhesive tape used immediately after smoothing.

- Consider using the FS caulking gun and FS jointing trowel for optimal results.

LIMITATIONS

You must be logged in to post a review.

| Elementlength | |||||||

| up to 1,5 m |

up to 2,5 m |

up to 3,5 m |

up to 4,5 m |

up to 2,5 m |

up to 3,5 m |

up to 4,5 m |

|

| Type of window frame material |

Minimum witdth of joints for a butled mounting b in mm |

Minimum witdth of joints for a inner mounting b in mm |

|||||

| Hard PVC (white) | 10 | 15 | 20 | 25 | 10 | 10 | 15 |

| Hard PVC and PMMA (dark) (colour extruded) |

15 | 20 | 25 | 30 | 10 | 15 | 20 |

| Hard PUR integral foam | 10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Wood-aluminium-window | 10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Aluminium-plastic sandwich frame (bright) |

10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Aluminium-plastic sandwich frame (dark) |

10 | 15 | 20 | 25 | 10 | 10 | 15 |

| Wooden window frame | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

£7.60 ex. VAT

Reviews

There are no reviews yet.