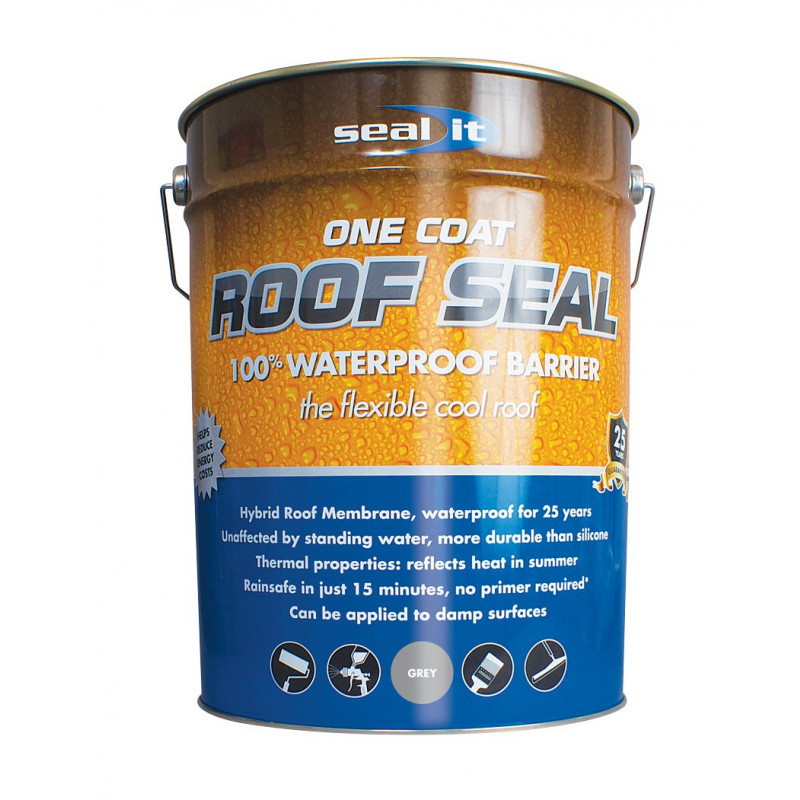

- Suitable For: roofs prone to ponding

- Area of use: EXT

- Application Method: roller

- Volume: 5Kg 20KG

- Container Type: tin

- Type: bitumen

- Colour: 2 colours

- Brand: Cromar

- Manufactuer: Cromar

- Box Size: Single Box

Data Sheets

Cromar Cromasol Reflective Roof Coating is an alcohol-based solar reflective coating designed to provide long-lasting protection against UV degradation and solar gain. Key points about Cromasol include:

- It is ready to use and should not be diluted, ensuring convenience in application.

- Specifically formulated for use on Mastic Asphalt, it is also suitable for application on BS747 Roofing Felts and fully cured bituminous liquid roof coatings.

- Cromasol does not attack bituminous substrates, preventing softening of asphalt and associated leaching into the drying film.

- Its carefully selected solvent-resin blend ensures effectiveness in protecting roofing substrates.

For more information on Cromar, you can visit their website here.

Cromasol Reflective Roof Coating is ideal for application on roofs prone to ponding, as Cromasol can endure prolonged immersion in water without deteriorating. Once applied, it becomes entirely water-resistant, unlike water-based reflective paints, even if exposed to rain before the film has fully cured.

APPLICATION

- Apply Cromasol only when both the surface and the product are dry, maintaining ambient temperatures between 5°C and 35°C.

- Utilize Cromasol as a final coat after preparing the roof for its intended purpose.

- Thoroughly mix the contents of the containers before application to ensure an even appearance.

- Regularly mix the product throughout the application process.

- Use a roller or airless sprayer to apply two coats of Cromasol to the prepared surface, allowing each coat to dry overnight.

- If feasible, apply the second coat perpendicular to the direction of the first coat.

- While the coating can be applied by brush, it requires extra care to avoid heavier and uneven applications.

- For optimal performance, it’s advisable to re-coat approximately every 5 – 7 years, depending on atmospheric conditions.

LIMITATION

- Users must ensure suitability for use, with Safety Data Sheets available upon request.

- Before use, carefully read the label for essential health and safety information.

You must be logged in to post a review.

| Elementlength | |||||||

| up to 1,5 m |

up to 2,5 m |

up to 3,5 m |

up to 4,5 m |

up to 2,5 m |

up to 3,5 m |

up to 4,5 m |

|

| Type of window frame material |

Minimum witdth of joints for a butled mounting b in mm |

Minimum witdth of joints for a inner mounting b in mm |

|||||

| Hard PVC (white) | 10 | 15 | 20 | 25 | 10 | 10 | 15 |

| Hard PVC and PMMA (dark) (colour extruded) |

15 | 20 | 25 | 30 | 10 | 15 | 20 |

| Hard PUR integral foam | 10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Wood-aluminium-window | 10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Aluminium-plastic sandwich frame (bright) |

10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Aluminium-plastic sandwich frame (dark) |

10 | 15 | 20 | 25 | 10 | 10 | 15 |

| Wooden window frame | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

£7.60 ex. VAT

Reviews

There are no reviews yet.