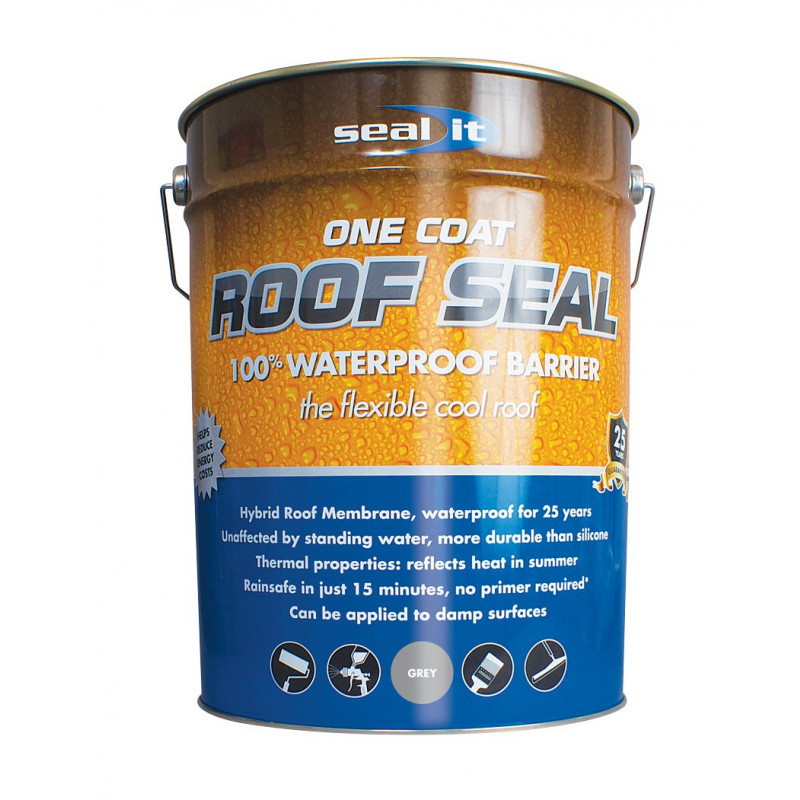

- Suitable For: treating friable and chalking surfaces

- Area of use: INT & EXT

- Application Method: brush

- Time to full cure: 4 - 8 hours

- Volume: 5L

- Container Type: bottle

- Type: treatment/primer

- Brand: AlphaChem

- Manufactuer: Cromar

- Box Size: Single Box

Cromar AlphaChem Stabilising Solution is a low viscosity solution designed to consolidate dusting, chalking, or friable surfaces, providing a stable base for redecoration.

Surface Consolidation: The solution effectively consolidates dusting, chalking, or friable surfaces, ensuring a suitable base for redecoration.

Versatile Application: With coverage ranging from 25-30m² per 5 liters on smooth surfaces, it adapts to various textured surfaces, though coverage may decrease on rough or highly absorbent surfaces.

Drying Time: Depending on atmospheric conditions, it typically dries within 4-8 hours, allowing for timely progress in redecoration projects.

Recoating Interval: For optimal results, allow 16 hours before recoating with masonry paints, ensuring a seamless finish and lasting protection.

For more information on our range of additives, please click here. Alternatively, for our full range from Cromar, click here.

For more information on Cromar, you can visit their website here.

Cromar AlphaChem Stabilising Solution is a low-viscosity solution, engineered to effectively consolidate dusting, chalking, or friable surfaces, thereby providing an ideal foundation for subsequent redecoration endeavors.

APPLICATION

- Prior to application of Stabilising Solution:

- Remove all friable and loose material using a stiff bristled brush and scraping.

- Treat any fungal growth with Moss & Mould Remover, applying liberally by brush or low pressure pneumatic spray.

- Allow 24 hours for the treatment to take effect and remove all debris.

- Application of Stabilising Solution:

- Typically, only one coat of Stabilising Solution is required.

- Brush the solution well into the surface to ensure complete absorption.

- Avoid leaving surplus material on the surface.

- Drying and Recoating:

- Allow treated surfaces to dry for a minimum of 16 hours before recoating.

You must be logged in to post a review.

| Elementlength | |||||||

| up to 1,5 m |

up to 2,5 m |

up to 3,5 m |

up to 4,5 m |

up to 2,5 m |

up to 3,5 m |

up to 4,5 m |

|

| Type of window frame material |

Minimum witdth of joints for a butled mounting b in mm |

Minimum witdth of joints for a inner mounting b in mm |

|||||

| Hard PVC (white) | 10 | 15 | 20 | 25 | 10 | 10 | 15 |

| Hard PVC and PMMA (dark) (colour extruded) |

15 | 20 | 25 | 30 | 10 | 15 | 20 |

| Hard PUR integral foam | 10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Wood-aluminium-window | 10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Aluminium-plastic sandwich frame (bright) |

10 | 10 | 15 | 20 | 10 | 10 | 15 |

| Aluminium-plastic sandwich frame (dark) |

10 | 15 | 20 | 25 | 10 | 10 | 15 |

| Wooden window frame | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

£7.60 ex. VAT

Reviews

There are no reviews yet.